How Are Granite Countertops Made?

How Are Granite Countertops Made?

Learn the Steps That Go Into Perfecting a Granite Countertop for your Kitchen

Learn the Steps That Go Into Perfecting a Granite Countertop for your Kitchen

Granite countertops add elegance and durability to any kitchen or bathroom, transforming spaces with their natural beauty. Let’s explore the intricate process from quarrying to installation that turns raw granted into stunning countertops.

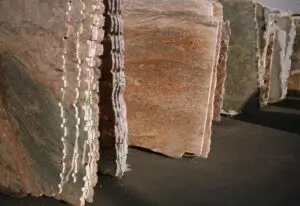

Quarrying – The process begins in granite quarries around the world, where large blocks of natural stone are extracted using mining techniques. Workers use drills and explosives to carefully separate the granite from the earth, ensuring minimal damage to the stone.

Cutting – Once quarried, the granite blocks are transported to production facilities. Here, they are cut into manageable slabs, using high-precision machinery like gang saws and diamond wire cutters. This step is vital for shaping the raw material into sizes suitable for countertops.

Polishing – After cutting, the slabs undergo a polishing process. Using progressively finer abrasives, the granite surface is smoothed to achieve the desired finish, ranging from matte to a mirror-like shine. This step highlights the stone’s natural patterns and colors.

Fabrication – The polished slabs are then custom-fabricated to fit specific designs and dimensions. This includes cutting the slabs to size, shaping edges, and making cutouts for sinks and fixtures. Fabrication requires skilled craftsmanship to ensure precision and quality.

Quality Control – Throughout the process, quality control is the top priority. Each slab is inspected for flaws, cracks, and color consistency. Only the best pieces proceed to the next stage, ensuring the final product meets the highest standards.

Sealing – To protect the porous surface of granite from stains and damage, a sealant is applied. This enhances the durability and longevity of the countertops, making them suitable for everyday use in busy kitchens and bathrooms.

Installation – The final step is the professional installation of the granite countertops in homes and businesses. This involves carefully transporting the fabricated pieces and securing them in place to ensure a perfect fit and finish.

Granite countertops are the result of a complex process that transforms raw stone into functional and beautiful pieces. From quarrying to installation, each step requires careful execution so that the final product enhances any space it occupies. Contact our experts to begin the process of redoing your countertops today.